Support

Customer service

Product support

Support

Customer service

Product support

SAVE MINIMUM 20% ON YOUR ELECTRICITY BILL

Replace your old machine with a new ITW Dynatec NGS gluing machine

BORRIES PRODUCTS IN THE AUTOMOTIVE INDUSTRY

Durable and direct marking of products is a prerequisite for traceability and thus an important part of quality assurance systems.

ROBOT - IS THE OUR NEW WORKER

Our existing and future business partners are given the opportunity to model new gluing tasks that arise in their production and try them out with us, even before they are actually included in the production technology.

MINE ROLLER PRODUCTION LINE

Our partner manufactures mining rollers, and we supplied them with a complete range of machines to facilitate their production process.

ITW Dynatec APEX High Speed Slot Glue Head

The ITW Dynatec APEX High Speed Slot Glue Head is an air-actuated, glue applicator with optional filter distributor. The head can be used with variable- or constant-pressure gluing equipment. The APEX is available in six different module configurations.

DEAR PARTNER!

Our company was founded in 2014. Our professionals have been working on the Hungarian market for several decades. With our reliability, knowledge and many years of professional experience we are still at the disposal of our partners.

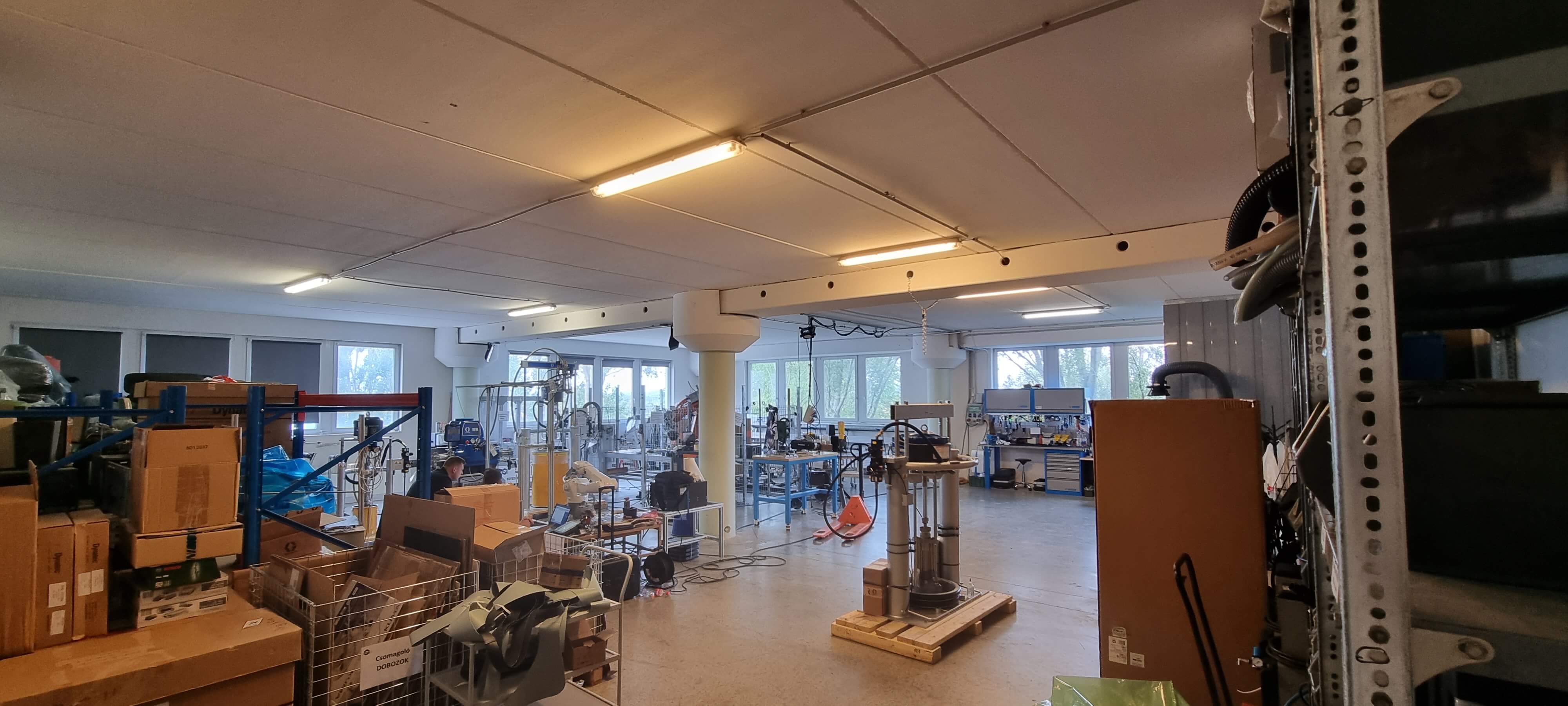

In Pécel, in the industrial park, in a cultivated environment, on 600 m2 , spacious office, well-equipped service, test equipment, warehouse, we are waiting for our customers' inquiries.

At I.A.S.G. Ltd. we offer complete solutions mainly in the field of industrial bonding and marking technology, which are always tailored to your needs!

In Hungary and the surrounding countries, we provide solutions for our partners in the field of adhesive technology with ITW Dynatec, Graco, Reka, Puffe Engineering, while in marking technology we offer solutions with Borries' manufacturing background.

Efficient industrial solutions:

- Joint developments

- Turnkey supply of customized production cells

- Condition assessment, repair and maintenance;

- Rapid service support for our foreign and domestic partners.

Our offer

Industrial adhesives

We have more than 20 years of experience in adhesive technology. Our equipment is always designed so that the bonding equipment and its components are easily accessible, maintainable and replaceable.

In industrial bonding, we provide a complete solution by developing the complete bonding technology at the request of our customers. We help you with the selection of the adhesive, the description of the bonding technology, 3D design software to model the production equipment, the location of the bonding equipment and other processes related to bonding.

The following criteria guided us in the selection of our suppliers:

- Providing reliable equipment from reliable suppliers.

- Innovative equipment that can always provide our customers with the latest trends.

- Flexible, fast customer service.

We have designed our product range to be complete. We offer solutions for both manual and automatic dispensing.

- Water dispersion gluing systems,

- Fluid gluing equipment,

- Single component room temperature, heated, hot melt adhesive sealant applicators,

- Two-component adhesive pouring equipment.

Industrial marking technology

Durable and direct marking of products is a key for traceability and thus an important part of quality assurance systems.

The aim of the process is to create a marking consisting of alphanumeric characters, unique symbols or DataMatrix codes, which allows the traceability of workpieces at any time based on the marked data (such as place of manufacture, date of manufacture, etc.), providing clear information and guidance to quality management.

It is used to mark brake discs, ABS systems, exhaust systems, engine and gearbox parts, type plates, etc.

Our well thought-out VIN integration solutions (scribe and vibropeening engraving) can be positioned automatically or manually on unpainted or painted bodywork. The marking process data is read from the central computer or data storage medium in the production.

Special custom characters, 2D codes or chassis numbers, as well as complex parts can be marked using chisel engraving, vibratory needle or laser technology.

Automation

Various gluing machines are typically integrated into existing production lines. They are integrated into production lines as semi-automatic/automatic equipment. I.A.S.G. can also offer solutions for such equipment on request. For industrial automation, the development of robotic applications is a priority. The use of robotics is becoming more and more common in automatic bonding tasks to ensure an accurate and correct bonding image. At I.A.S.G., the design and implementation of robotic applications is also at the forefront. Our Hungarian partner in this field is Kuka Hungária Kft.

The most common industries are Automotive and their suppliers

- White good industries

- Packaging technology.

Our company pays great attention to the optimal fulfilment of the customer's needs and ideas. To meet these requirements, we can supply our robotic cells and target machines in accordance with the customer's requirements, in accordance with the technical parameters and technological specifications. In each case, we select the most suitable technology for the task in hand, taking into account the quality and quantity requirements of the parts to be produced, as specified by the customer.

I.A.S.G. Ltd. develops complete systems for the application of robots in gluing technology. The design and construction of the equipment and the programming of the robots are carried out at our site in Pécel.

DO YOU HAVE A QUESTION ABOUT THE PRODUCTS?

| Weboldalunk sütiket (cookie) használ. A honlap további használatával hozzájárul a sütik használatához

További információk: Adatkezelési tájékoztató |

Elfogadom

|